- Doosan Enerbility

- Doosan Bobcat

- Doosan Mottrol

- Doosan Fuel Cell

- Doosan Tesna

- Doosan Robotics

- Doosan Mobility Innovation

- Doosan Logistics Solutions

- Doosan H2 Innovation

- Doosan Investments

- Oricom

- Hancomm

- Doosan Magazine

- Doosan Bears

- Doosan Cuvex

- Doosan Corporation Electro-Materials BG

- Doosan Corporation Digital Innovation BU

- Doosan Corporation Retail BU

- Doosan Yonkang Foundation

- Doosan Art Center

- Doosan Business Research Institute

-

01

Minimize the impact of EHS on management activities by establishing an EHS management system and complying with applicable legal and other requirements.

-

02

Place the highest priority on the health and safety of all employees and suppliers, for which the best working environment and operational capabilities shall be secured and maintained.

-

03

Improve the quality of life for customers and contribute to environmental preservation by developing eco-friendly technologies, products and services.

-

04

Actively take part in the environmental protection efforts of local communities, fulfill social responsibilities, and engage in open communication with interested parties based on integrity and transparency.

-

05

Ensure all employees and suppliers are aware of and join our efforts toward achieving full compliance with our EHS policy.

Management

System

Criteria of DSRS

(Doosan EHS

Rating System)

-

01

Leadership

Evaluation of management’s awareness of EHS risks, resource support for EHS risk management activities and exemplary actions taken to guide such activities.

-

02

Planning and Administration

Evaluation of effective planning and follow-up action plans to achieve EHS goals.

-

03

Risk Evaluation

Evaluation of all the processes and pre-risk assessment activities related to identifying risks for effective EHS management.

-

04

Human Resource

Evaluation of systems for securing, retaining and improving the core competency of EHS-related human resources.

-

05

Compliance

Evaluation of compliance with local laws, regulations, industrial codes, control systems and social responsibilities regarding EHS.

-

06

Project Management

Evaluation of anticipating and managing risks throughout the entire life cycle of an unusual project such as establishing or expanding a new business site.

-

07

Training and Competence

Evaluation of training systems and its operation in order to improve the EHS competences of the organization.

-

08

Communication and Promotion

Evaluation of effectiveness and efficiency of all communication systems on EHS issues such as executive general meetings and on-site TBM meetings.

-

09

Risk Control

Evaluation of identified risk control (technical, design, management control, etc.) and operation of protective systems including personal equipment.

-

10

Maintenance and Inspection

Evaluation of effective maintenance, inspection and MOC (management of change).

-

11

Contractors and Suppliers

Evaluation of system management including partner selection process, definition of responsibility, core competence development, proper supervision, monitoring and performance rating.

-

12

Emergency Preparedness

Evaluation of effective emergency plans, training systems for emergency response groups and special equipment maintenance systems to minimize damage in the event of an emergency.

-

13

Incidents Investigation

Evaluation of incident investigation systems and competence of analyzing the root causes of incidents and reporting practices of all non-conformances including accidents.

-

14

Risk Monitoring

Evaluation of risk monitoring systems, and continuous monitoring to check if follow-up measures have been taken after a non-conformance is identified.

-

15

Results and Review

Evaluation of efforts to continually improve the system by assessing the performance against the EHS goals.

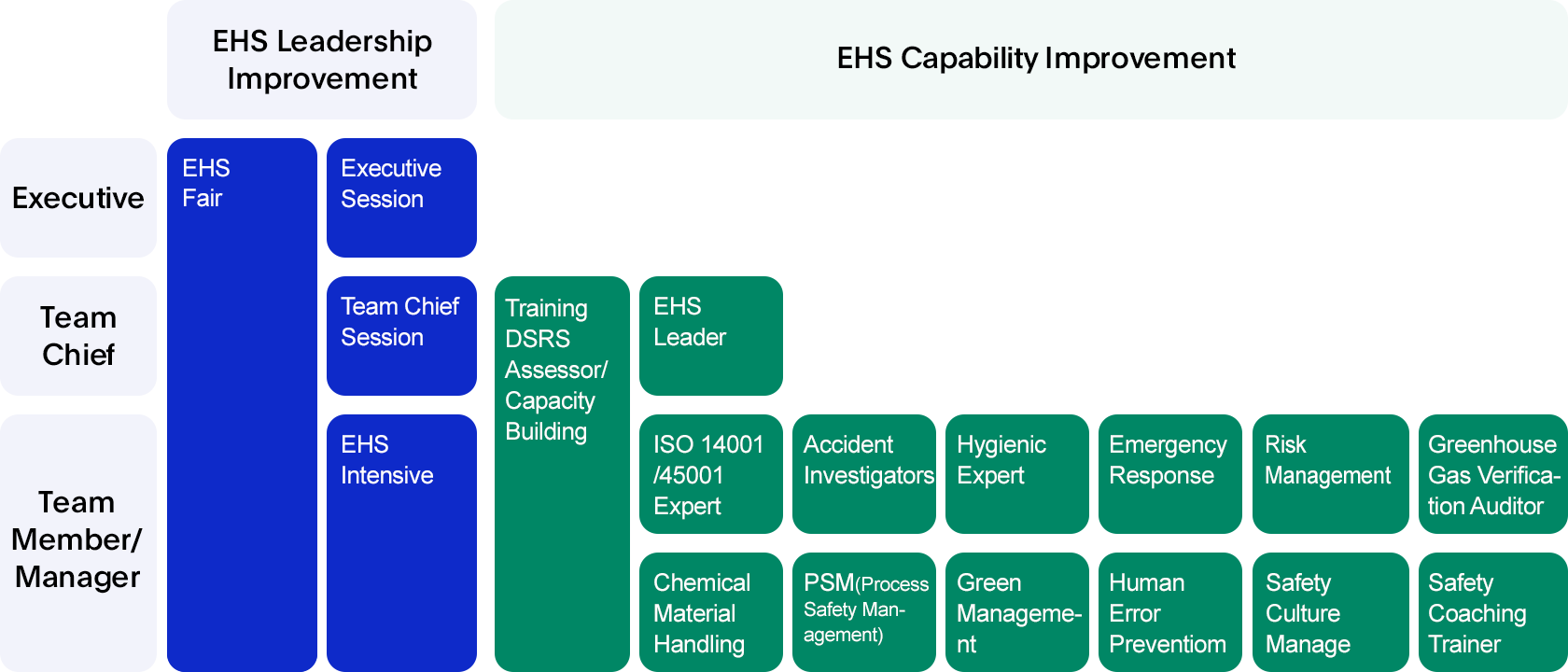

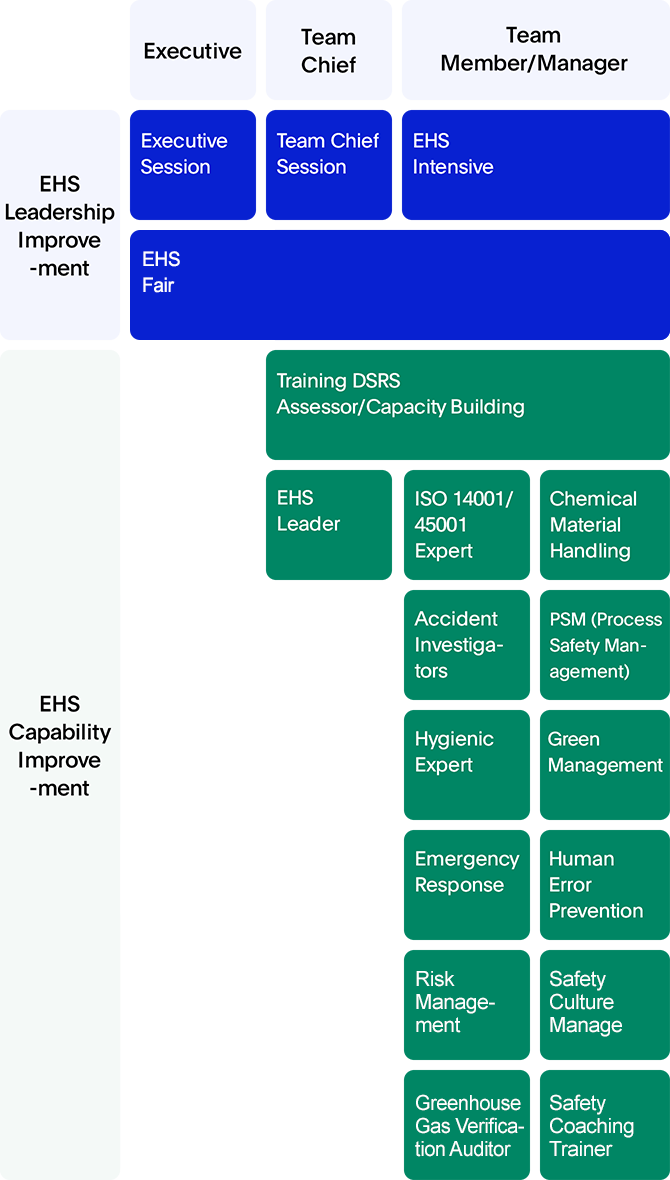

Training

Program